Method and Simulation

From the feasibility study to the Method. From theory to practise.

Artisan Engineers

Like an artisan, FASI shares the process, completing a detailed and precise study of the engineering of the project. From the result of the feasibility study and the analysis of the production process, FASI develops the methodology and the simulation, guaranteeing that each product and component has a robust and reliable process.

A realistic simulation

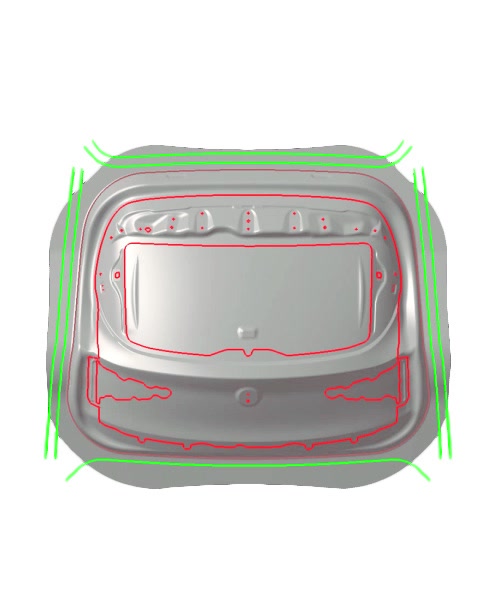

All components go through an incremental simulation, completing the entire process with an analysis of the post-trim spring-back; to verify the results and define the intervention strategies necessary to eliminate breakages, compressions, undulations and dimensional errors.

Our Experience for your satisfaction.

The analysis of sheet metal deformation in the entire process is completed and analysed using Autoform software. The precise and constant work done to check and compare the results obtained in each singular detail, has enabled us, over years of work, to determine discrepancies between the theory and the practise, thereby reducing the time to complete the design and put the dies into production.

A quality product

Every particular detail is analysed and optimised to be harmonised with the entire production process. Method and Simulation, today, are two indispensable forms of analysis of the engineering process, which were created to achieve one result- a product of quality.