Springback

Springback is the geometric variation of an element at the end of the molding process and occurs due to the…

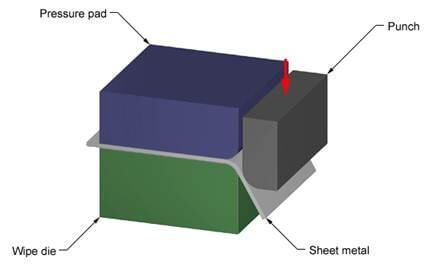

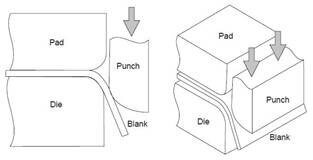

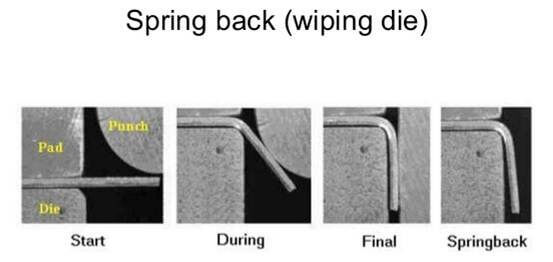

Springback is the geometric variation of an element at the end of the molding process and occurs due to the release of the forces when the tools are opened. Upon completion of the molding process, drawn and elongated parts return elastically and therefore compromise the dimensional accuracy of a finished element.

Due to springback, the final shape of the element is modified, making it difficult to produce the element itself. This means having to deal with and solve some practical problems: firstly, the prediction of the final geometry of the element after the springback and, secondly, the planning of adequate instruments to compensate the effects of the elastic return.

With the use of new materials, then, the number of problems increases. Elements printed with these materials, in fact, are more affected by the elastic return than elements drawn in conventional steel. As for the classic defects of forming, such as breaks and wrinkles, the deformation of the sheet is decisive. In case of springback, these models are not sufficient to predict deformation. The stresses, therefore, are decisive and a superior precision is essential.

During the design of the tools, the springback is compensated by the software so that the element coming out of the mould is immediately of the dimensions and tolerances required. The simulation software is not only able to calculate the springback since the design phase, but it can also compensate for it. In this way, the molding processes are optimized with a consequent decrease of the production costs.

Fasi Press